COM-HPC – the next-gen Computer-on-Module standard

COM-HPC is specifically designed to address the ever-increasing performance demands and bandwidth needs of all the new and upcoming edge and embedded server applications that cannot be served by previous Computer-on-Module specifications. As such it will be the game changer for systems covering todays and upcoming demands in the digitization era.

The COM-HPC standard is hosted by the PCI Industrial Computer Manufacturing Group (PICMG). It is broadly supported as of 2023 by up to now 29 companies and an even higher number of experienced engineers in the various COM-HPC working groups. The standardization effort at PICMG was initiated by congatec. Christian Eder, director product marketing at congatec, holds the position of the chairman for the technical subcommittee.

To learn about the general advantages of the Computer-on-Module concept and the available COMs standards besides COM-HPC, COM Express, SMARC module and Qseven, please click here: https://www.congatec.com/en/technologies/embedded-computer-on-modules/

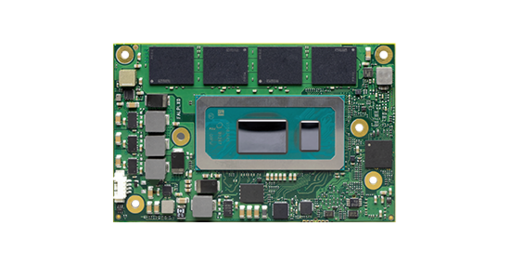

COM-HPC Client

Unmatched features and performance for next-gen edge and embedded computing devices with powerful graphics

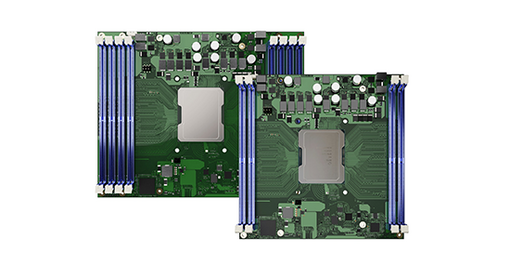

COM-HPC Server

The new standard for powerful, sustainable, and upgradeable edge servers in harsh environmental conditions

COM-HPC ecosystem

Everything designers need for instant prototyping and roll-out of high-performance embedded and edge computing systems

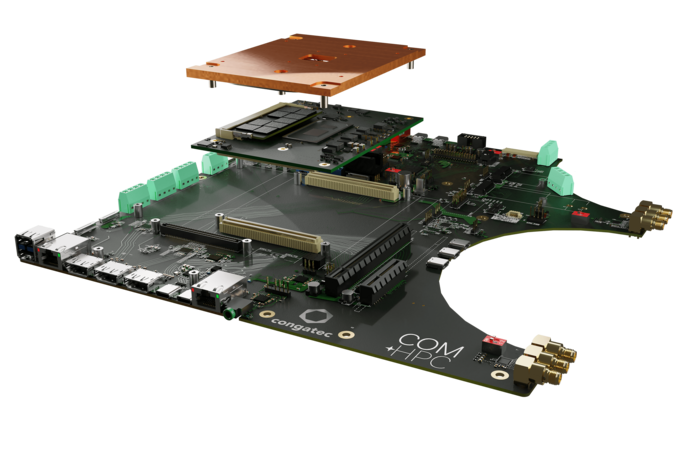

From handheld to server – All designs based on one standard

COM-HPC offers a complete ecosystem for realizing future-oriented digitization projects most agile and successful. COM-HPC Computer-on-Modules are available with 3 different pin-out types and 6 different sizes for an easy development of applications ranging from powerful Small Form Factor (SFF) devices to graphics oriented multi-purpose designs as well as rugged edger servers with high core count and extensive memory capacities. Corresponding carrier boards from congatec allow designers a direct start into application development, and congatec’s cooling solutions optimized for each individual module enable most effective heat dissipation.

Freely combinable manageable modules

COM-HPC modules are enabled by concept to host not only x86 and Arm processors but also assisting computing accelerators like GPUs, ASICS, and FPGAs. Another unique capability of COM-HPC is that designers can combine different modules and footprints on one carrier board. Furthermore, COMHPC features a platform management interface (PMI) specification, leveraging a simplified feature set of the Intelligent Management Platform Interface technology (IPMI) for easy remote management options, even when the system is turned off.

Facts, Features and Benefits of COM-HPC

| Facts | Features | Benefits |

| Vendor independent standard | COM-HPC Modules are available from many different vendors, all exchangeable within the same pin-out and footprint | Increased availability and reliable multi source strategy to improve production scalability and resilience against supply chain issues |

| Three different pinouts and 6 different sizes | COM-HPC modules come as COM-HPC mini, COM-HPC Client and COM-HPC Server modules | From SFF applications to full blown server designs, developers can leverage the same design principles for different applications or complete product families reducing NRE and increase design security. |

| Processor and computing core agnostic | COM-HPC modules can host any computing core from x86 multicore processors and Arm SoCs to graphics processing units as well as ASICs and FGPAs | Identical design approach for all different computing designs accelerates and simplifies application design and improves time to market. Reliable upgrade paths across processor generations increase application life cycle and ROI (Return On Investment). |

| Support of future oriented interface technology | Support of more and higher bandwidth I/Os including PCIe up to Gen 5 and beyond, USB4 / Thunderbolt 4 and up to 8 x 25 GbE | Future oriented interface technology for an extra-long application life cycle without bottle necks in data transfer rates |

| Increased power budgets | Higher performance thanks to power budgets of up to 107 watts on credit card sized modules, 251 Watts for COM-HPC client and 358 Watts for server designs | Increased power budgets provide more headroom for designers to leverage most powerful CPUs, I/Os and memory, which all require more power for more performance. OEMs should look for vendors offering also optimized cooling solutions. |

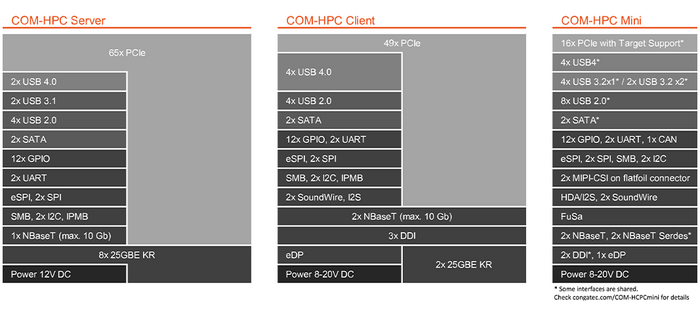

Application oriented sizes and feature-sets - the COM-HPC specifications at a glance

COM-HPC Mini (upcoming)

One credit card sized footprint

95 mm x 60 mm

400 pins - single connector pin-out for smallest designs with fully fledged functionality

Up to 107 watts power consumption

Up to 16 PCIe lanes

Up to 4x 10 GbE

Up to 4x USB4

Up to 3x Video

Rugged by design thanks to soldered memory

Functional Safety support

MIPI CSI camera support

CAN bus

COM-HPC Client

Three footprints

Size A: 95x120 mm

Size B: 120x120 mm

Size C: 120x160 mm

800 pins - dual connector pin-out optimized for graphics oriented multi-purpose designs

Up to 251 watts power consumption

Up to 49 PCIe lanes

Up to 2x 25 GbE & 2x 10GbE

Up to 4x USB4

Up to 4x Video

Up to 4 SDRAM sockets

Functional Safety support

MIPI CSI not supported

CAN bus not supported

COM-HPC Server

Two footprints

Size D: 160x160 mm

Size E: 160x200 mm

800 pins - dual connector pin-out optimized for headless servers with highest interface and networking bandwidth

Up to 358 watts power consumption

Up to 65 PCIe lanes

Up to 8x 25 GbE & 1x 10GbE

Up to 2x USB4

Headless

Up to 8 DRAM sockets

Functional Safety support

MIPI CSI not supported

CAN bus not supported

Note: Not all I/Os are available in parallel. Some pins are shared.

Feature Overview

Further COM-HPC ecosystem building-blocks

COM-HPC specification

The COM-HPC specification is described in 3 documents

- COM-HPC® Module Base Specification Revision 1.15

- COM-HPC Platform Management Interface Specification

- COM-HPC Embedded EEPROM Specification

The specification documents are available for purchase:

COM-HPC Carrier Design Guide

This document provides information for designing project specific Carrier Boards for systems using COM-HPC Modules. This document is a design guide and not a specification document. It should be used together with the COM-HPC Base Specification, with other industry specifications, with silicon and component vendor’s documentation and with your COM-HPC Module vendor’s product documentation.

COM-HPC webinars, trainings and services

Our new carrier board design training program to impart best practice knowledge on how to design-in leading Computer-on-Module COM-HPC modules. The goal is to provide system architects with a quick, easy, and efficient deep dive into the design rules of this PICMG standard. The training courses will guide engineers through all the mandatory and recommended design essentials and best practice carrier board schematics. It will efficiently simplify OEM’s carrier board design projects.

This webinar will give you an overview of the technology, applications, requirements and capabilities of this new PICMG standard.

COM-HPC Videos

Do you want to learn more about COM-HPC?

Download our whitepapers!

COM-HPC carrier board designs

COM-HPC is the upcoming new standard for modular high-end edge servers. It provides significantly faster and almost twice as many interfaces as COM Express. As a result, carrier board design requirements are increasing exponentially. How can developers prepare for the new challenges?