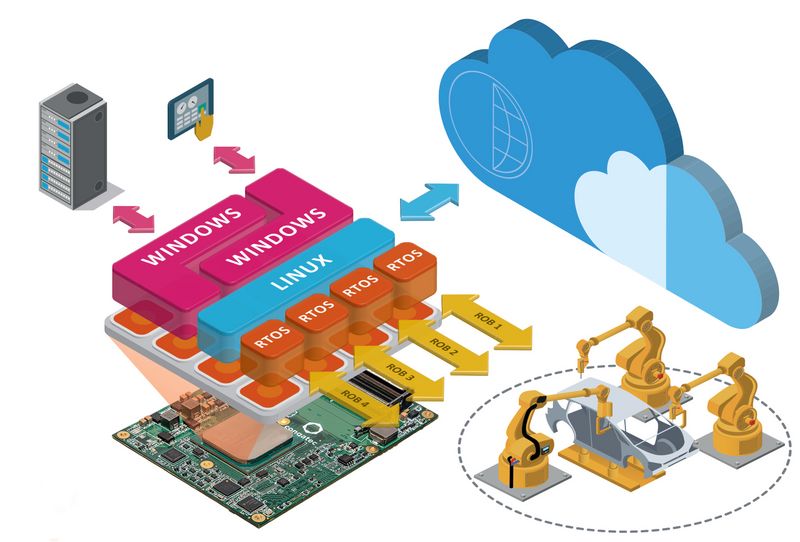

Deggendorf, Germany / Tokyo, Japan, 10 May, 2017 * * * congatec – a leading technology company for embedded computer modules, single board computers and embedded design and manufacturing services – spotlights its new high-end embedded computing portfolio for robotics and real-time automation at the Embedded Systems Expo & Conference (ESEC 2017) in Japan (West Hall 1F, Booth W4-20). Designed from the ground up to meet highest ‘made in Germany’ quality standards, the comprehensive product portfolio includes the unique hypervisor technology from German real-time virtualization expert Real-Time Systems, consolidating the congatec robotics computing offering in a single, application ready, 4-in-1 hardware platform for PLC, HMI, IoT and Industry 4.0 systems.

congatec’s new hardware virtualized platforms improve the integration of previously stand-alone robotics systems and build the fundament for the next generation of smart, cyber-physical controlled systems and deep learning humanoid robots. They also increase the utilization of costly hardware while reducing investments as well as operational costs through lower energy consumption.

“Japanese robotics and automation vendors and German embedded real-time computer vendors are predestined to form an outstanding cooperation to generate most innovative high quality robotics and real-time control systems. We are therefore very excited about the Hannover Declaration of close cooperation between Japan and German industry announced at this year’s CeBIT fair. This spirit of collaboration will accelerate our support for Japanese robotics and automation vendors, enabling them to stay on top of both the global humanoid and industrial robotics market as well as connected industrial and medical systems,” explains congatec CEO Jason Carlson.

The application ready combination of embedded boards and computer-on-modules from congatec with real-time hypervisor technology from Real-Time Systems is perfectly suited for connected robotics, industrial machine controls and medical systems. Engineers benefit from application ready and functionally validated real-time platforms that significantly reduce their verification and validation efforts; a comprehensive documentation package that is ready for own certifications; and personal integration support that does not stop at driver or library settings but delivers the entire real-time capable, virtualization ready platform. Together, these benefits enable engineers to most efficiently exploit the full congatec multi-core embedded board and computer-on-module range, from Intel® Atom™, Celeron® and Pentium® processors (codename Apollo Lake) up to Intel® Core™ and Xeon® D processors (Codename Kaby Lake) and AMD G-Series and R-Series, for their various applications.

World’s first next generation virtualized robotics server showcase

In a demo system congatec showcases the world’s first virtualized robotics server platform built on the innovative COM Express Type 7 server-on-module standard recently launched by the PICMG. This brand new next generation server platform enables application specific designs of industrial edge and fog severs technologies at lowest customization cost. The hardware virtualized server hosts the PLC control for the robot, the HMI for the operator, the IoT gateway for remote/mobile monitoring and maintenance as well as the powerful 10 GbE Industry 4.0 gateway for real-time collaboration of machinery in cyber-physical smart factories. Big Data storage is hosted on PCIe connected SSDs in highly efficient and secure RAID-5 configuration. Predictive maintenance analytics of system fans and SSDs are executed by the rule engine of congatec’s new cloud API for IoT gateways. The system’s cloud is virtualized on the IoT gateway partition as well. It can also be automatically mirrored to central clouds.

More information about congatec’s application ready virtualized platforms for connected real-time robotics and controls can be found online at

http://www.congatec.com/en/technologies/com-express/com-express-type-7.html