High-performance cooling solutions that can take the heat

An essential part of every reliable embedded and edge server design

An essential part of every reliable embedded and edge server design

COM Cooling Solutions

Cooling Technologies for Embedded Computing

Cooling isn't just an add-on for embedded systems—it's the key to unlocking peak performance and reliability. At congatec, we've mastered the art and science of thermal management for Computer-on-Modules (COMs).

Our innovative cooling solutions are tailored for each module, engineered from the ground up to maximize performance in any environment. From compact heat spreaders, active coolings to advanced heatpipe adapters, we offer the thermal expertise to keep your systems running at their best.

congatec's cooling technologies at a glance

Increased reliability

Overheating is responsible for more than 50% of electronic equipment failures. congatec's cooling solutions keep CPUs cool, enhancing reliability, uptime, and total cost of ownership (TCO).

Increased performance

Modern processors adjust their performance based on the available thermal budget during high workloads. congatec's efficient cooling solutions allow processors to maintain higher frequencies for longer periods.

Fully sealed designs

Our high-performance heat spreaders and innovative heat pipe adapters simplify the design of fully sealed, fanless systems and edge servers for the most challenging applications.

Real-time capabilities

With congatec cooling solutions, embedded systems can avoid thermal throttling, maintaining deterministic behavior even in demanding environments.

Smaller designs

Patented cooling solutions from congatec distribute heat effectively across the heat sink, allowing for smaller designs without compromising heat dissipation.

Heat Spreaders

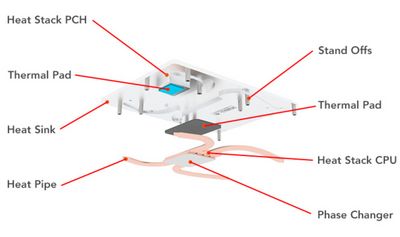

congatec heat spreaders efficiently transfer heat from the hot spot on modules to the system’s casing or cooling elements, utilizing thermal stacks and phase change materials for optimal heat convection. Compliant with COM-HPC, COM Express, Qseven, SMARC and Pico-ITX standards, these spreaders simplify integration and ensure compatibility across designs.

Our heat spreaders are ideal for hygiene-sensitive and fully sealed designs like medical devices, rugged outdoor infrastructure installations, in-vehicle applications, and AMRs and AGVs.

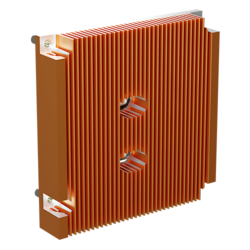

Passive cooling solutions

Designed for environments requiring reliable, noise-free operation, passive cooling solutions with cooling fins offer excellent heat dissipation in systems with directed airflow. These solutions are ideal for rugged applications like medical devices and HMIs in industrial automation, helping to lower maintenance costs and extend Mean Time Between Failures (MTBF).

Our passive cooling solutions are ideal for rugged applications like medical devices and human machine interfaces (HMIs) in industrial automation. Passive is particularly popular in these use cases because of the lower maintenance costs it enables in point of sale (POS), point of interest (POI), kiosks, and other designs that are to be operated remotely.

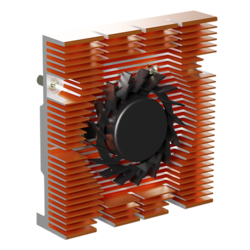

Active cooling solutions

When heat output exceeds passive capabilities, our active cooling solutions employ high-quality fans for enhanced performance, with adjustable speeds to balance cooling and noise levels. This adaptability ensures optimal performance under varying operational conditions. High-quality fan motors, sophisticated fan geometry, and ball bearings ensure quiet operation and a long service life.

Our active cooling solutions are designed for applications where performance is paramount. They are designed to operate reliably in harsh environments such as factory floors, vehicles, and outdoor areas.

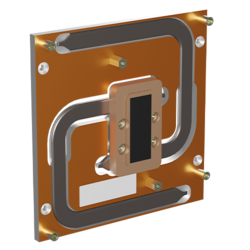

Patented flat-pipe design

For modules with high-performance processors on COM Express and COM-HPC modules, congatec utilizes its patented flat-pipe design. This unique technology brings the efficiency of heat pipes to standards-compliant heat sinks without increasing their size. The integrated flat pipes distribute the waste heat from the hot spots extremely efficiently over the entire heat sink, greatly improving heat dissipation.

Spiral springs with defined spring tension, as well as the heat pipe itself with its flexible height, put optimum pressure on the processor, ensuring the best heat conduction. Moreover, manufacturing tolerances in the soldering process or height differences of the chips can be balanced in every direction.

Hot spots, such as the CPU, are most efficiently cooled so they have more thermal headroom for high-performance operation for a longer time period, increasing system performance and efficiency.

Heatpipe adapter

Designs like rugged edge requiring highest performance in all conditions are best served with our innovative heat pipe adapters. They transfer the heat directly from the hot spots on the module to standard heat pipes with 6 or 8 mm diameter enabling a fanless design for even the highest performance COM-HPC Server or COM Express Type 7 modules.

Wherever highest edge-server performance in an ultra-rugged, ultra-reliable and ultra-slim design is required, our heat pipe adapters are the best choice. They are available with support for industrial temperature ranges down to 0°C and up to 60°C.

congatec cooling solutions scale from credit card to server

Cooling solutions vary based on form factor and CPU heat dissipation requirements. Whether for compact modules or high-performance server-class systems, congatec offers scalable solutions to meet diverse performance needs.

| Form factor | CPU TDP Range | Heat Spreader | Passive Cooling Solution | Active Cooling Solution | Heatpipe Adapter |

| SMARC | < 15W | ✓ | ✓ | ||

| Qseven | < 12W | ✓ | ✓ | ||

| COMe Type 6 low power | 6-12W | ✓ | ✓ | ||

| COMe Type 6 high power | 15-45W | ✓ | ✓ | ✓ | ✓ |

| COMe Type 7 | up to 100W | ✓ | ✓ | ✓ | ✓ |

| COM-HPC Mini | 12-28W | ✓ | ✓ | ✓ | |

| COM-HPC Client low power | 15-45W | ✓ | ✓ | ✓ | |

| COM-HPC Client high power | around 65W | ✓ | ✓ | ✓ | |

| COM-HPC Server low power | up to 70W | ✓ | ✓ | ✓ | ✓ |

| COM-HPC Server high power | up to 135W | ✓ | ✓ | ✓ |

Our dedicated services

Customized cooling solutions

For specific mechanical or thermal performance requirements, congatec provides custom-designed cooling solution.

Design review

Optimize your design with congatec’s guidance and take advantage of our on extensive experience in cooling design and development.

Performance review and thermal simulation

Rely on our advanced services and tools to ensure optimal performance and adherence to demanding standards.

Thermal photography

Gain valuable insight into your cooling and system design, accurately identify hot spots and find the ideal heat distribution to optimize overall reliability and performance.

aReady.COM

Get all required hardware and software building blocks for a reliable system design to improve efficiency, time to market and reliability of your solutions.